Sustainable Plastics Recovery guide

Chemistry Australia, as part of the global plastics industry, has developed the Sustainable Plastics Recovery guide to improve how used plastic products are recovered conserve precious resources and energy in the process.

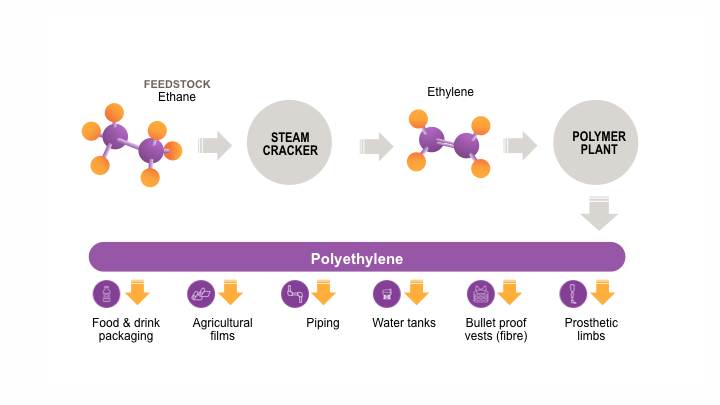

Chemistry Australia has a policy position of working to eliminate plastic waste to landfill. After serving out a useful purpose as a product, plastics are able to be recycled into a range of material or energy types. Plastic products can be mechanically recycled and re-manufactured into a variety of new products. Compostable plastics are able to become compost in commercial facilities. Plastics can also be used as an alternative fuel or energy source.

Generally, all of these options are better than plastic’s resources being locked up and wasted in landfills. Importantly, the different recovery methods each have an environmental contribution in reducing both materials and energies needed to make new products. The waste hierarchy provides a valuable guide to selecting suitable methods.

A Guide to Sustainable Plastics Recovery provides the fundamental principles to be used by governments, industry and communities in best recovering plastics.

A Guide to Sustainable Plastics Recovery provides the fundamental principles to be used by governments, industry and communities in best recovering plastics.

This guidance is a non-binding statement of principles and values relating to the management of plastic products at end-of-life.

It is based on a document developed at the 19th Annual Global Meeting on Plastics and the Environment, held in October, 2008 in Rio de Janeiro, Brazil. The meeting was attended by plastics industry associations from Argentina, Australia, Brazil, Canada, China, Europe, India, Japan, South Africa and the USA.

This group of associations, and the plastics industries in various parts of the world they represent, recognise the value and importance of responsibility, leadership and global cooperation in managing environmental issues relating to plastics. This is consistent with the role of plastics providing solutions to the challenges of climate, population and economic change.

The group recognises the role of all types of plastics and that the selection of materials for a given application should be based on technical merit, over whole-of-life, supported by sound science.